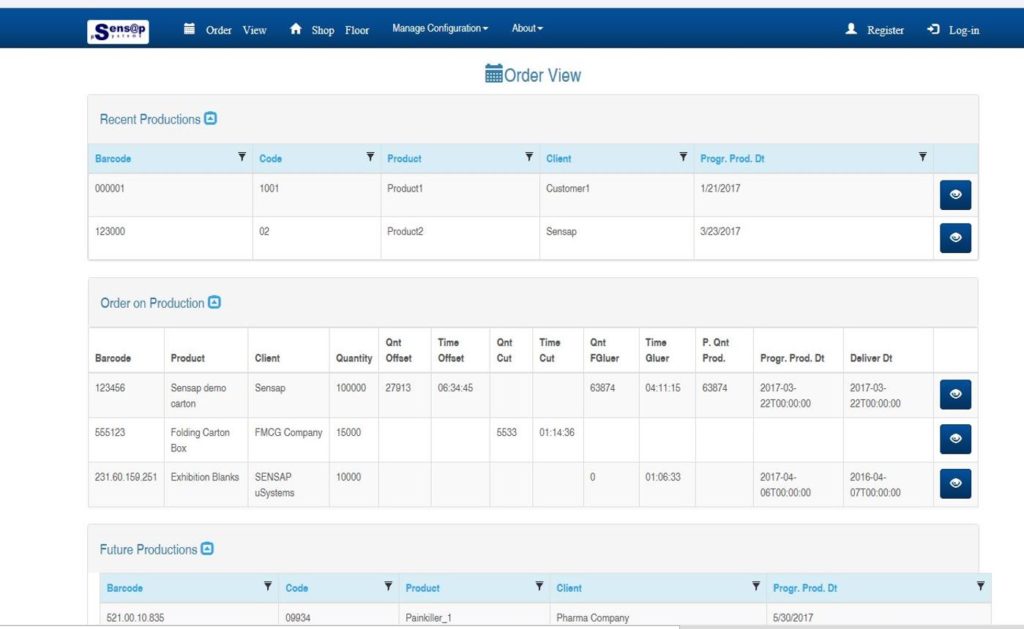

SENSAP Swiss AG was founded on April 1st, 2011 in Zurich Switzerland as the industrial development arm of the AutoID department of company SENSAP SA, based in Athens (Greece). Founded on SENSAP’s broad visibility in the logistics and manufacturing sectors, rich intellectual property, and world-class expertise, SENSAP Swiss, develops and markets SBOX Traceability software suite and INTERGA series of hardware modules that target manufacturing companies and logistics enterprises in the Food & Beverage, Pharmaceuticals & Cosmetics, Carton-Conversion, and Apparel business sectors.

The company’s solutions adopt best-of-breed Internet of Things (IoT) architectures, which enable the integration and orchestration of multiple heterogeneous and distributed sensors in a scalable way. SENSAP has experience in the integration of solutions based on standard-based IoT architectures, such as the architectures introduced by EPC Global and Open Geospatial Consortium (OGC), and based on de-facto open source architectures (notably based on the Global Sensor Networks-GSN and AspireRFID open source projects). SENSAP Swiss AG is an Independent Software Vendor (ISV) and Systems Integrator, providing turn-key solutions that address IoT solutions including Machine Vision Systems, AutoID-centric (RFID, Barcode) and Business Activity Monitoring (BAM) based on multi-sensor systems. SENSAP offer Materials Handling Automation, comprising Hardware, Middleware, and Applications Software, for Human-Driven Operations, with reference to:

- Manufacturing and Warehouse Operations Execution.

- Asset Management and Preventive Maintenance.

- Materials-Flow Traceability throughout the entire Product Supply-Chain and Lifecycle.

In addition, SENSAP develop custom vision quality inspection solutions in demanding industrial environments which lead to a complete range of machine vision quality, in-line inspection products, for the Carton-Conversion, Pharmaceuticals-and-Cosmetics and Food-and-Beverage industries.

SENSAP has profound experience in the development of Cyber Physical Systems (CPS) manufacturing solutions and components that allow for data acquisition from the shop-floor, with emphasis on paper and packaging manufacturing business. The company has also implemented projects that involve the whole CPS solution development lifecycle, from solution inception to deployment in the factory. These successful combined industrial projects regarding acquisition data from the production floor and the gain experience through European funded projects led to the Daedalus IoT device, part of the Integra products line.