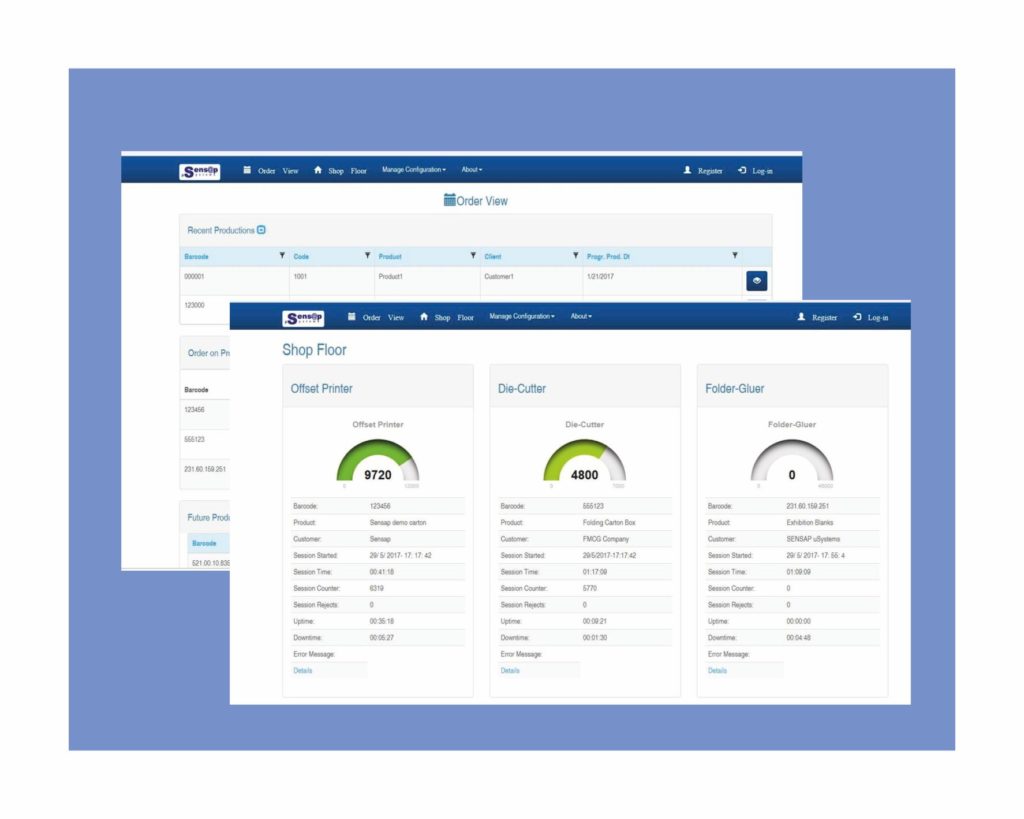

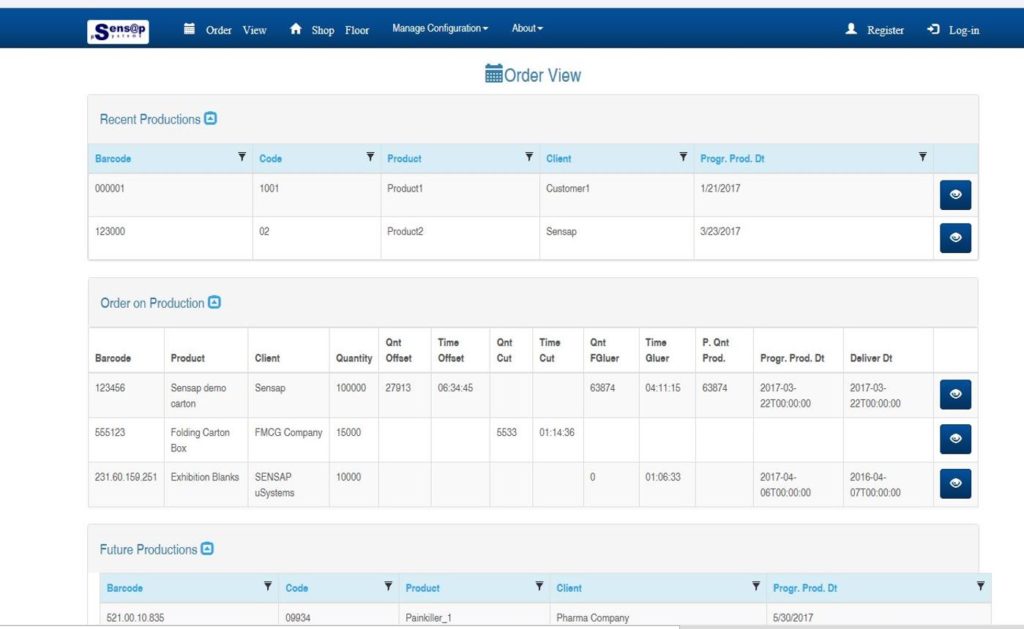

is an automation unit that focuses on monitoring production floor. Through the management of sensors that are integrated into production machines, automatically collects and analysis production data. It provides operators with accurate information about

machine usage and the progress of work at hand in real time.

SENSAP™ INTEGRA Daedalus eliminates the need for inaccurate, erroneous and time-consuming manual data entry on paper, touchscreens, or mobile terminals. It handles the sum of the logging process thus allowing operators to focus on their work.